REPASSA » Our Solutions » High Temperature Resistance Materials

High Temperature Resistance Materials

Sterilisation-in-place(SIP) often causes problems for sealing materials with the cycle times being the main concerns.

GYLON BIO-PRO® seals, modified and restructured PTFE material, is pre-formed and stress controlled for high temperature usages. It promotes longer SIP cycles and provides you a better peace of mind.

How is GYLON® Made?

GYLON® Advantages at a Glance

- Stable dimensions — No intrusion, no cold flow, high recovery

- Temperature resistance — Can be used at all process temperatures and with high temperature fluctuations

- Will not become embrittled or crack due to temperature exposure.

- Chemical resistance — Almost universal chemical resistance, FDA compliant, meets USP Class VI

- Reduces inventory

- Reduces risk of improper installation

- Maintains excellent sealing characteristics under vibration, flange misalignment and high temperature differentials

- Can be installed in a wide range of pressure connections

- Reduces downtime and costs

- Resistant to all SIP and CIP processes

- Approvals — EN 1935/2004, USP Class VI, FDA-compliant

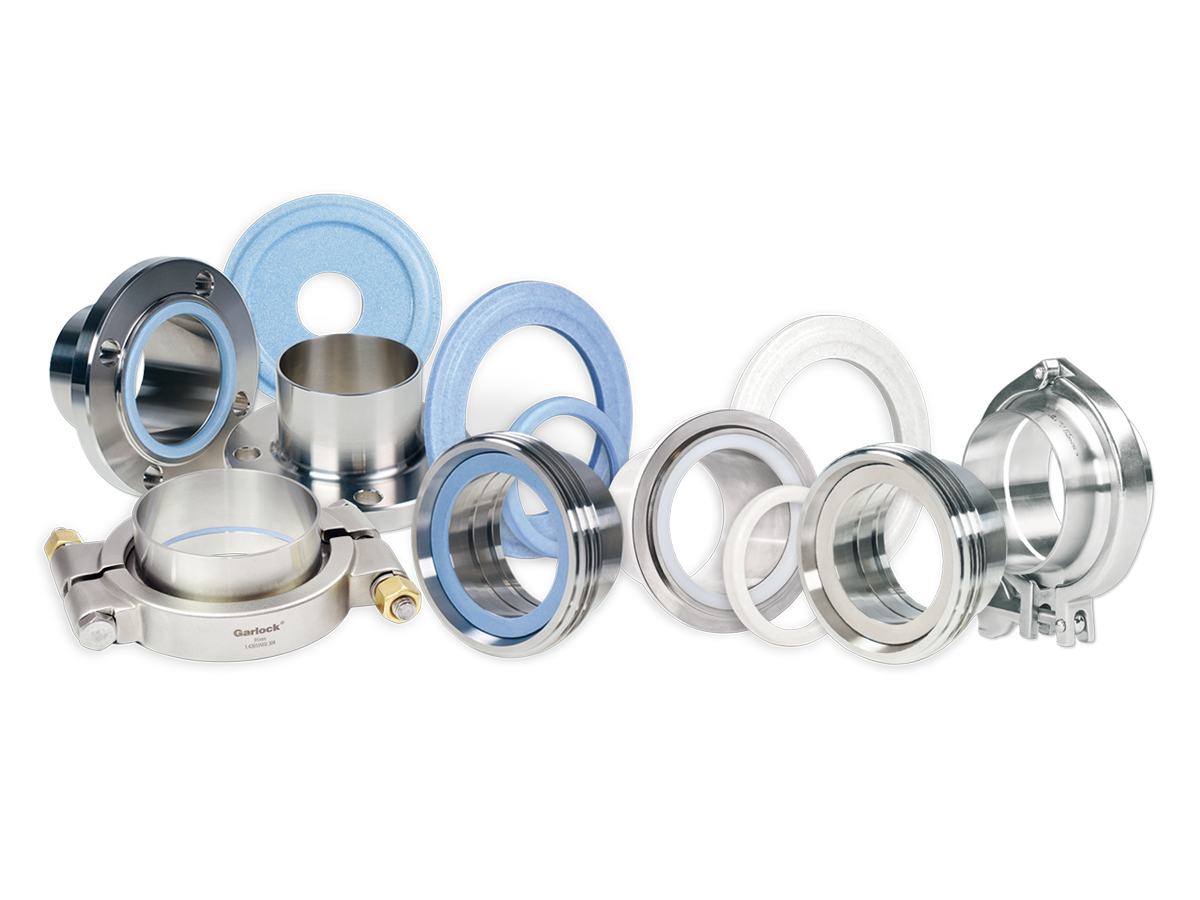

GYLON® on different types of Connections

Camlock connections are the standard connection for quick coupling in the food industry as well as the chemical industry.

Manufactured from our proprietary GYLON® style 3522 modified PTFE, GYLON® BIO-PRO PLUS™ delivers best in class performance across all critical…

Sanitary High-Pressure Clamps for hygienic connections according to DIN EN 32676 and ASME BPE 2016 for the Food- and Pharma Industry.