For High Viscosity Media (Typically 1,000 – 1,000,000 cps)

Our approach to your high viscosity product transfer comes from understanding what is upstream and downstream of your process. Every little detail allow us to advise the suitable pump to use for your application.

If you require higher suction and might run into running dry situation, we have our Air or Electric operated Double diaphragm pump.

If you require higher discharge pressure, we have our circumferential piston pump.

If you require more gentle approach on your solids in your product, we have our twin screw pump as your solution.

Air Operated Diaphragm Pumps

The Tapflo air operated diaphragm pump sanitary series is particularly designed to meet the requirements of the food, beverage, pharmaceutical and cosmetic industries. High suction, Dry running are some of the major features for this pump series.

Made to be clean

Our design allows for total visual inspection of the wetted parts. There are no hidden areas where bacteria can grow. The manifold clamps and the housing screws are simply removed for complete disassembly and cleaning. The pump is also designed for cleaning and sterilization in place – C.I.P. and S.I.P. After such operations, the pump is easily turned in its support for drainage.

Drain the pump by turning the pump in its support

ATEX certified pumps

All sanitary pumps are available in explosion proof ATEX marked version. They are supplied with earth connection and conductive materials; conductive centre section and diaphragms in PTFE (conductive back) or EPDM (conductive).

Typical applications

| Industry | Example of application |

| Dairy products | Milk, cream, yogurt, cream cheese, melted cheese |

| Grossery | Ketchup, mayonnaise, tomato products, mustard |

| Beverages | Flavours, colouring, fruit juice |

| Bakery | Dough, ingredients |

| Brewery | Beer, flavours, colouring, wort |

| Hygiene | Soap, toothpaste, schampoo |

| Cosmetics | Cream, alcohol, perfume |

Electrically Operated Diaphragm Pumps

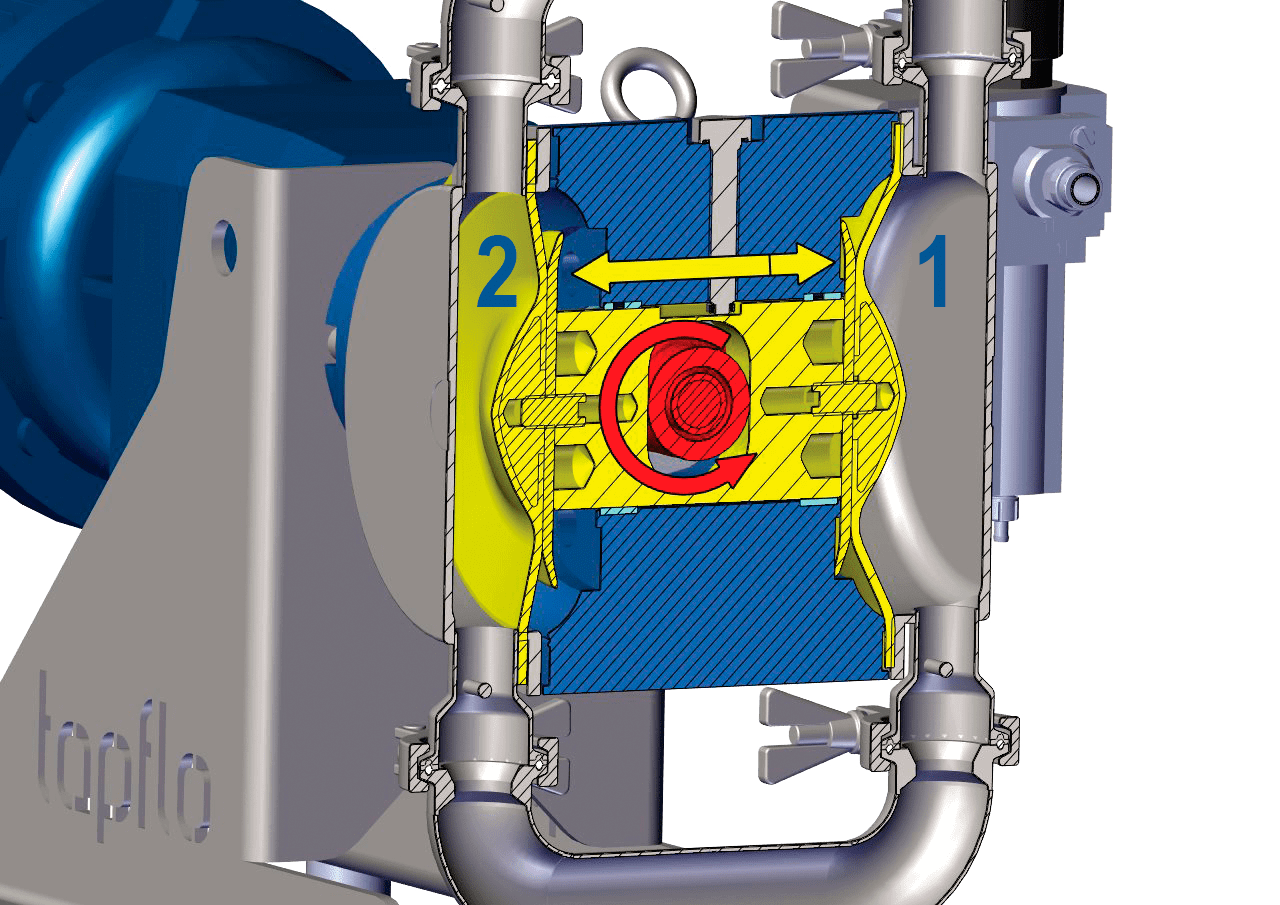

The Tapflo electric diaphragm pump is driven by a gear-motor. In this type of pump there is a need to change rotary motion into reciprocating one. It is obtained by an eccentric shaft with a cam and piston. The rotary movement of the shaft (red part) is transferred to the reciprocating movement of the diaphragm shaft (yellow part).

FEATURES & BENEFITS

![]() Low energy cost

Low energy cost

Electricity cost < compressed air cost, high efficient (IE3 class) drive

![]() Long diaphragm lifetime

Long diaphragm lifetime

Pneumatic and mechanical support of the diaphragm

![]() Run dry without damage

Run dry without damage

Easy to use, no need of guarding device

![]() Low spare parts cost

Low spare parts cost

Pump has almost identical design of the wetted side as standard Tapflo air operated diaphragm pump therefore many spare parts are the same

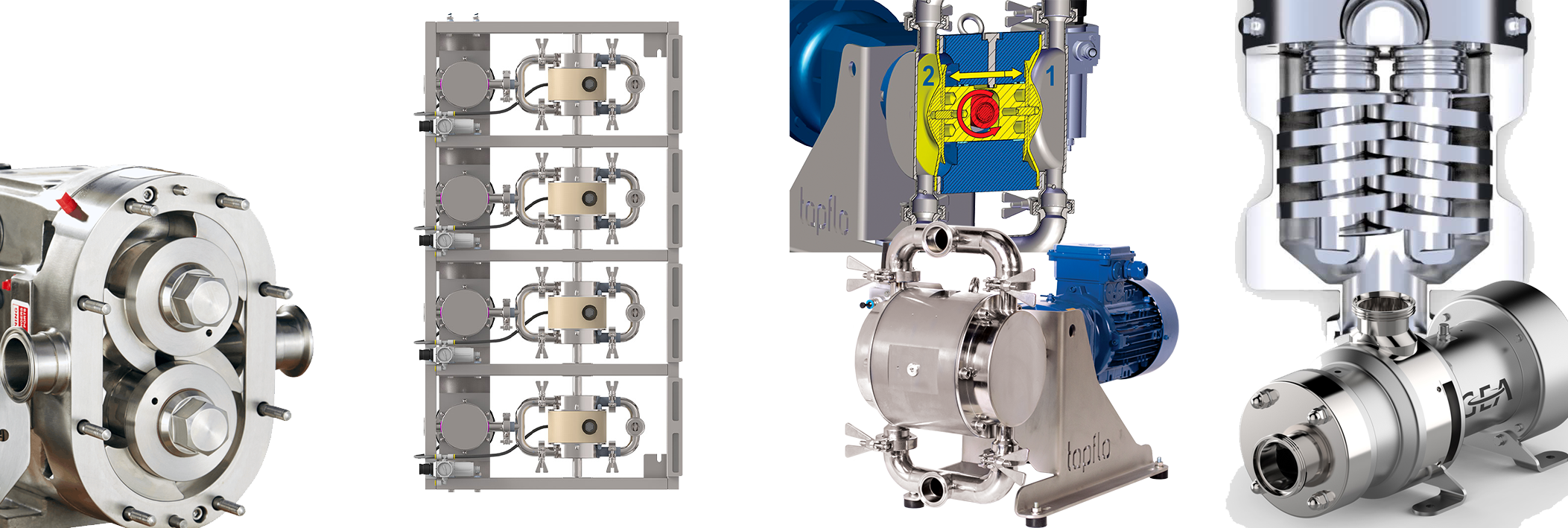

Twin Screw Pumps

GEA Hilge NOVATWIN is the new flexible twin screw pump series in the GEA VARIPUMP line.

The best pump for your application

The GEA Hilge NOVATWIN allows production and cleaning with only one pump by variable speeds up to 3000 rpm. Its self-priming capability of up to 8 meters opens new application fields.

The pump design ensures gentle product handling with almost no pulsation, which makes the pump especially suitable for large and delicate particles.

The system pressure of 30 bar enables also high-pressure applications.

Variable combinations

The pump housing can be equipped with various hardened screw combinations. Reverse flow direction as well as flexible port positions are possible on individual customer demand. This allows the GEA Hilge NOVATWIN to adapt to different applications, media and operating conditions.

Shaft Seals

To accommodate different applications and media, GEA Hilge NOVATWIN are available with single or double mechanical seals.

The mechanical seals are inboard seals placed in the optimum position in the pump to ensure outstanding lubrication and cooling. They also comply with the hygienic design criteria in CIP and SIP processes.

Seal face materials are carefully selected to suit the specific media. Standard materials are silicon carbide /silicon carbide with EPDM elastomers (FDA-compliant).

Connections

- Sterile flanges to DIN 11864-2 / DIN 11853-2

- Threads to DIN 11851

- Clamps to DIN 32676

- Sterile threads to DIN 11864-1 / DIN 11853-1

- Other connections available upon request. This includes SMS, RJT, IDF, etc., and special sterile threads and flanges

GEA Hilge NOVATWIN Variants

- With bare shafts

- With geared or standard motor and coupling mounted on stainless steel base frame

- With stainless steel motor shroud

- Mounted on trolley

Applications

The GEA Hilge NOVATWIN pumps are suitable for a variety of applications, such as:

Dairy

- Cream Cheese

- Butter

- Yoghurt

- Sour Cream

- Ice Cream

Food

- Sugar solution

- Chocolate

- Sauces

- Soups

- Mayonnaise

- Pastes

- Oils & Fats

- Prepared Salads

- Pet Food

Beverage

- Smoothies

- Juice Concentrate

- Pre-mixes

- Brewing Yeast

Pharma & Biopharma

- Neutraceuticals

- Blood Products

- Vaccines

- Enzymes

- Cell cultures

Personal Care & Home Care

- Cosmetics

- Body & Skincare

- Fabric care

- Household Cleaners

Additional options

Thermal Jackets

This option allows to either heat or cool the pump chamber depending on the temperature requirements for the pumped media.

Vertical installation

The complete GEA Hilge NOVAWIN pump can be installed vertically to reduce the footprint in your skids.

Hardened pump housing

For abrasive media screws and additionally the pump housing can be hardened to ensure a longer lifetime of the pump.

Program overview

| Pump model | NOVATWIN 10 / 15 | NOVATWIN 20 / 25 | NOVATWIN 30 / 35 | NOVATWIN 40 / 45 | NOVATWIN 50 / 55 | NOVATWIN 60 / 65 |

| Max. flow rate (m³/h) Product | 12 | 30 | 65 | 125 | 215 | 310 |

| Max. flow rate (m³/h) CIP | 20 | 50 | 115 | 160 | 215 | 310 |

| Max. differential pressure (bar) | 16 | 25 | 25 | 25 | 25 | 25 |

| Max. speed (rpm) Product | 1,760 | 1,760 | 1,760 | 1,760 | 1,760 | 1,760 |

| Max. speed (rpm) CIP | 3,000 | 3,000 | 3,000 | 3,000 | 2,400 | 2,000 |

| Standard connection size (mm) | 50 | 65 | 80 | 100 | 125 | 150 |

| Max. particle size (mm) | 17 / 25 | 25 / 33 | 31 / 43 | 38 / 53 | 46 / 62 | 55 / 74 |

Circumferential Piston Pump

ZP3 Series is Innovation in Positive Displacement Pumps

The enhanced design of Ampco’s patented ZP3 series positive displacement pumps is now leading the industry. It sets the standard for PD circumferential piston pump technology with a simplified yet state-of-the-art design that’s reliable, durable and available fast – within two weeks.

Engineered Excellence. The ZP3 Series features patented technology and unmatched CIP-ability – while maintaining maximum efficiency, ease of maintenance, and greater uptime.

Innovation Achieved. This Ampco Original has a new front-loading seal design that eliminates all dead zones in the pump. Plus the stainless steel gearcase, bearing retainers, splash plate and cleanout plugs deliver maximum performance. The ZP3 technology and features make it the best value in sanitary positive displacement pumps today.

ZP3 Series

Circumferential Piston Pump Features

- 304 Stainless Steel Gearcase

- Alloy 88 Rotors

- Front Loading Seal Design

- Hardened Seal Faces Generate Less Heat

- Stainless Steel Bearing Retainers

- 17-4ph Shafts – more than 3 times the yield strength of 316

- Helical Gears

- 4-Way Mounting

- Multiple Access Threaded Grease Zerks

- Anti-Microbial Lube

- Gasketed Stainless Steel Cleanout Plugs

- Stainless Steel Splash Plate

ZP3 Series Performance Overview

Models: 22

Max Discharge Pressure: 500 PSI / 34 BAR

Max Flow Rate: 452 GPM / 103 m3/hr

Max Viscosity: 1,000,000 cP

Seal Specifications: 2 Seal Options