REPASSA » Our Solutions » Liquid Product

Filling Machine for Liquid Products

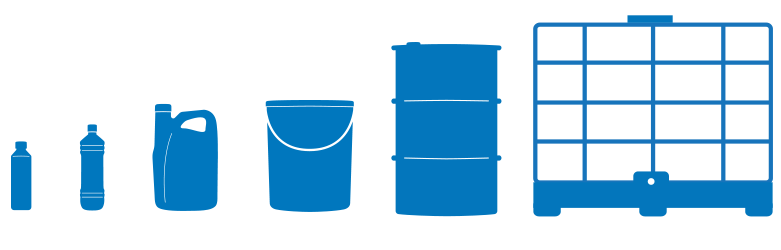

From 100ml to 1000L, we supply rinsing, filling, capping & labelling machines, as well as end-of-line solutions dedicated to the packaging of liquid products. The range of Semi-Automatic to Fully-Automatic machines served the Foods, Pharmaceuticals, Home & Personal Care, Dairy & Oils industry

SEMI-AUTO BOTTLE RINSER

SEMI AUTOMATIC BOTTLE RINSER

Semi Automatic Bottle Rinser to rinse bottles with water or ozonated water. Bottles are hand loaded into the rinser pockets in the star wheel as it rotates. A pump supplies rinse water under pressure to the rinse nozzles to rinse the inside of the bottles.

The bottles then drain before being ejected to an external bin. The star wheel is a change part that is quickly changed out when bottle sizes are changed. A very basic control system is supplied with the machine allowing the operator to adjust the speed to the desired output.

The bottles then drain before being ejected to an external bin. The star wheel is a change part that is quickly changed out when bottle sizes are changed. A very basic control system is supplied with the machine allowing the operator to adjust the speed to the desired output.

SEMI-AUTO FILLING AND CAPPING MACHINE (500ML - 30L)

PACK’R dosing carrousel performs two operations :

- Filling : The filled quantity is controlled by the weight of the product in the container.

- Control after filling : Weight control allows checking the measured quantity in comparaison with the target, self-correction for any drift, and making statistics and production ratios.

NORM :ATEX / Explosion proof design

CADENCE :Up to 8 CPM

CAPACITY :From 500ml to 30L

CAPS :Screw capsPush-on capsFlexspout

SEMI-AUTO PALLET DRUM/IBC FILLER-CAPPER (200L - 1,000L)

Pallet drum/IBC filler-capper

- Easy and quick installation

- Ergonimic and compact design

- Easy manual operation

- Many options and ancillary equipment available: – Conveyor systems and controls – Manual bunging and crimping tools – Customized controls and interfaces – Operator platforms and cleaning stations

NORM :ATEX / Explosion proof design

CADENCE :UP TO 40 DRUMS / HOUR

CAPACITY :From 20L – 200L drums and IBCs

CAPS :Metal bungPlastic bungMetal cap sealsPlastic cap seals

AUTOMATIC STEP BY STEP FILLER CAPPER (500ML - 5L)

- Filling : The filled quantity is controlled by the weight of the product in the container.

- Control after filling : weight control allows checking the measured quantity in comparaison with the target, self-correction for any drift, and making statistics and production ratios.

- Many possible configurations and applications allow you to conceive a very flexible production line which is able to evolve according to requirements

- Several capping stations – Several formats on each station – Ultra-fast format changeovers

AUTOMATIC HIGH SPEED ROTARY FILLER CAPPER (100ML - 5L)

- Filling : the filled quatity is controlled by the weight of the product in the container.

- Control after filling : weight control allows checking the measured quantity in comparaison with the target, self-correction for any drift, and making statistics and production ratios

Many possible configurations an applications allow you to conceive a very flexible production line which is able to evolve according to your requirements:

- Several capping stations

- Heatsealing function available

- Several formats on each station

- Ultra-fast format changeovers

NORM :ATEX / Explosion proof design

CADENCE :UP TO 600 CPM

CAPACITY :From 100ml to 5L

CAPS :Screw caps/Crimp cover/Flexspout

AUTOMATIC COMPACT ROTARY FILLER CAPPER (500ML - 30L)

- Filling : the filled quantity is controlled by the weight of the product in the container.

- Control after fillling : weight control allows checking the measured quantity in comparison with the target, self-correction for any drift and making statistics and production ratios.

- The PACK’R COMPACT capping system in the outfeed starwheel allows to manufacture very flexible machines with high productivity

- Screw cap : up to 60 cps/min

- Push-on caps : up to 100 cps/min

- Full format changeovers (containers + cap) last less than 30 minutes

NORM :ATEX / Explosion proof design

CADENCE :UP TO 40 CPM

CAPACITY :From 500ml to 30L

CAPS :Screw caps / Flexspout

AUTOMATIC PALLET DRUM/IBC FILLER-CAPPER (200L - 1,000L)

- Integration of full automatic functions: – Bung detection with 2D camera – Bung removal – Product filling (with automatic grounding for hazardous execution) – Bung replacement ( with torque control) – Cap seal crimping – Conveyor and controls system easily integrated with filler

- Labour cost reduction (no human intervention)

NORM :ATEX / Explosion proof design

CADENCE :UP TO 40 DRUMS / HOUR

CAPACITY :From 20L – 200L drums and IBCs

CAPS :Metal bung/Plastic bung/Metal cap seals/Plastic cap seals

AUTOMATIC HIGH SPEED PALLET DRUM/IBC FILLER-CAPPER (200L - 1,000L)

- High-speed filling machines – Similtaneous executions of automatic operations on each station : debunging, filling, bunging, crimping – Fast format changeovers (Click&Play tooling System)

- Precise positionning of drums during transfers from station to station (held in place by grippers.)

- Quick return on investment (no giveway/ high production capacity)

NORM :Food contact

CADENCE :UP TO 120 DRUMS / HOUR

CAPACITY :Drum From 60L to 220L

CAPS :Metal bung/Plastic bung/Metal cap seals/Plastic cap seals