Tablet Deduster & Metal Detector

Tablet Deduster improves dust condition in your packaging rooms, preventing equipment to malfunction or leading to poor seals on bottles and blister packages.

Six primary requirements to consider when you select a tablet deduster.

- 1. Identify your minimum and maximum tablet sizes. Their size, along with the speed at which they enter the deduster, determine the machine volume required to transport and dedust the tablets effectively.

- Know the maximum output of the tablet press for each size tablet you make.

- Know your tablets’ hardnesses and the nature of the dusts since tablet hardness factors into deduster size. Chewable or effervescent tablets, for example, may require very different dedusters.

- Determine whether a metal detector should accompany the deduster.

- Decide how many containers will collect the dedusted tablets. If they must be collected in two or more containers, a diverter will be needed, which adds to the overall height; which must be taken into account.

- Determine the outlet height of the press and the inlet height of the collection container(s). To calculate this, measure the distance from the floor to the bottom of the tablet outlet chute and from the floor to the top of the collection container. These two distances determine the deduster’s conveying height—the height required to reach the collection container.

Metal Detector

Metal detection is not only about putting your product thru and it will detect all metal contaminants. To safeguard your process, we have to look into the Aperture and Sensitivity of the Metal Detector

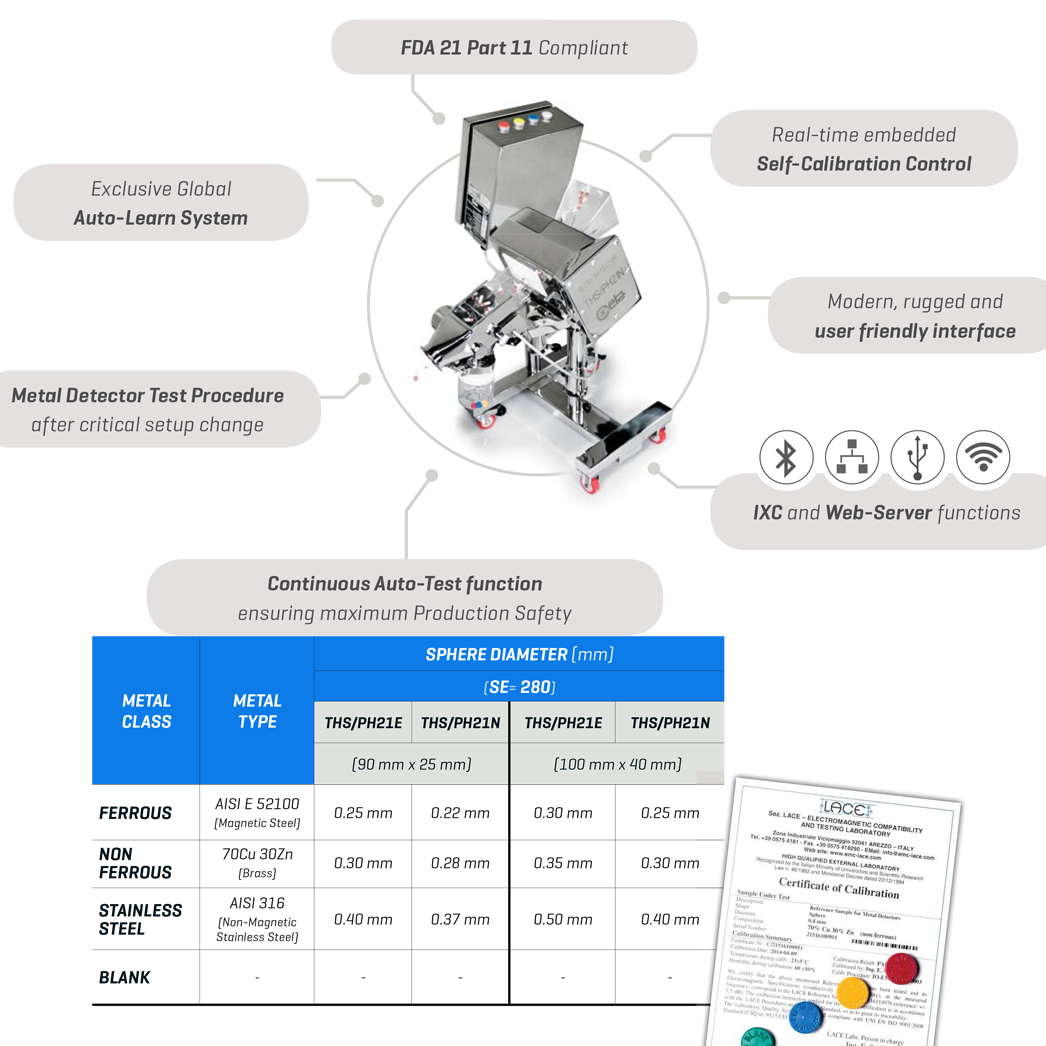

CEIA PHARMACEUTICAL METAL DETECTOR design and Construction is compliant with GMP criteria. FDA Code Title 21 Part 11, no manual calibration or tuning is needed and exclusive Auto-Learn system for pharmaceutical products are some of the main key features of CEIA.

Features

CEIA THS/PH21N Metal Detection Systems feature extremely high detection sensitivity towards contaminating metals, whether ferrous, non-ferrous or stainless steel, even when these are present in tiny quantities

FDA 21 Part 11 compliant

The THS/PH21 Metal Detector Series is a high-sensitivity, high-precision measuring instrument. The response from the device is used to directly command ejection of the contaminated product and to verify that it has in fact been eliminated.

FDA Code Title 21 Part 11 prescribes rigorous criteria for access to programming and computer data protection, which have been fully adopted in the CEIA THS/PH21 Series firmware. User access is only possible via a User Name and Password login under the control of the System Administrator, who programs and manages individual user profiles and user functions. As a result, the requirements for security, integrity and traceability are satisfied.

All events performed by the THS/PH21 Metal Detector are recorded in a data log to comply with FDA Part 11 protocol and assist in root cause analysis. The events include detection, ejection, program operations, passwords and periodic functional test phases using standard test samples.

Real-time embedded self-calibration control

The Self-Calibration control allows maximum repeatability and performance consistency over time and with environmental changes.

Continuous auto-test function ensuring maximum production safety

Special electronic stimuli are sent to the transmission and reception chain of the THS/PH21 Series Metal Detector, causing variations in the detection signals which provide checks on detection characteristics.

These variations are compared with the reference values stored in the memory of the metal detector at the time of the factory calibration test. This produces an automatic certified check of the system’s sensitivity.

Exclusive global auto-learn system

The Auto-Learn System provides simultaneous maximum sensitivity to all metals starting from a single learning transit. The THS/PH21 Series employs an exclusive Auto-Learn system for pharmaceutical products, which allows optimization of the detection sensitivity to all metals with the maximum speed and precision, equivalent to hundreds of conventional learning transits. This results in levels of precision and efficiency never before obtained.

New diagnostic tools

The THS/PH21 Series introduces new tools for the installation and maintenance technician to measure the environmental compatibility of the metal detector. These are functions that would otherwise have required the intervention of external instrumentation, now implemented in the microcomputer control of the device itself. The measurements include general mechanical and electromagnetic environmental compatibility.

Modern, rugged and user friendly interface

- Industrial rate design

- Rapid data entry with extended keyboard

- Easy to read, high-contrast graphic display

- Rugged, antivandalic stainless steel keyboard. Organic graph display with extremely high contrast (3000:1) and a viewing angle up to 180°, and an extended alphanumeric keypad for quick keystrokes.

- Protection degree: Power Supply Box: IP65 (IEC60529); Antenna & Ejection System: IP67

- 40 users available (including administrator)

- Quick access function. A new function, activated simply by pressing a dedicated key, allows the most frequently-used functions to be directly recalled. These functions are programmable by the operator.

Ejection system specifications

- Monolithic AISI 316L Stainless Steel Body

- Advanced mechanical and electronic solutions guarantee the integrity of the inspected product

- Extremely quick response time provides full safety in the ejection of contaminated product

- Double confirmation system carefully monitors and controls the complete opening and closing of the ejection flap

- Bin full sensor kit (on request)

BT wireless communication connectivity

In the THS/PH21 Series, local connection to the maintenance technician’s computer no longer requires physical access to the interior of the detector or the use of unwieldy connection cables. The BT wireless communication connection can be used for programming, monitoring of the signals via the CEIA MD-Scope program and the transfer of the data contained in the Metal Detector’s events memory.

Network communication capabilities

The Metal Detector can be linked to an Ethernet network (optional IXC module required). In association with the THS Production Plus Software it enables remote management of production, collection of all technical and operational events, generation of statistical and traceability reports in compliance with FDA 21 CFR part 11 requirements.

MD-Scope

Software Diagnostic Package complete with connector cable and hardware key:

- Remote programming

- Signal input/output

- Alarm threshold and amplitude of the signal

- Oscilloscope functionalities

THS Production Plus

- Connects and Acquires Data from Multiple THS Detectors via Ethernet LAN

- Provides Connection to an External Database and Definition of a Programmable Block of SQL Instructions for each Metal Detector Event

- Enables Data Base Management and Back-Up of Metal Detector events

- Report Data Exportable in HTML and CSV format

- Provides User Authentication and Manages Electronic Signatures and Records

- Allows Data Integrity and Operator Auditing

- FDA Requirements Compliant, Title 21 of the Code of Federal Regulations (CFR)

- E-mail sender

IXC Module

- Gateway to THS Production Net Management System

- Integrated Web-server

- Dual 100base-T Ethernet

- Dual Full Speed USB interface

- Wi-Fi 802.11b/g

- 100,000 events internal data logger

- Additional web-server functionality

Web-server interface

- Built-In MD Scope. The MD Scope functions (including oscilloscopes) are available to every user connected to the Metal Detector via Ethernet or WiFi.

- Status. Replicates every message displayed by the THS (updated each 5 s).

- Products. Displays the list of products stored into the THS memory, the selected product is shown in green. This page allows the product to be changed.

- Products export. Allows selection of all or part of the products stored in the THS memory in order to export them.

- Products import. Allows importation of all or part of the products exported.

- Buffer export. Allows exportation of events occurred in a selected time frame.

- Configuration backup/restore. Allows backup or restoring of the connected system configuration.

- Configuration export/import. Allows the configuration to be exported or imported from other Metal Detectors of the same model, installed on the same system.

Options

Antistatic infeed conveyor kit for Dust Tight (DT) version

Dust Tight Infeed conveyor eliminates electrostatic charges during the product’s passage. Particularly efficient in case of tablets and capsules’ inspection.

Antistatic infeed conveyor kit for Wash In Place (WIP) version

Wash In Place Infeed Conveyor with nozzles eliminates electrostatic charges during the product’s passage. Particularly efficient in case of tablets and capsules’ inspection.

Bin full sensor

Added sensor that activates when the reject bin is full with rejected products. When activated, an alarm message on the detector’s display warns the operator of the full condition.

External USB plug kit

Allows USB connector of the IXC card to be mounted outside of the Power Control Box.