For high aggressive resistance materials

GYLON® White Style 3510

The product with the broadest chemical resistance. The preferred choice for extremely aggressive media including hydrofluoric acid, aluminum fluorides, chlorine/alkali, caustic potash solutions and electroplating baths. Inhibits the polymerization (“pop-corning”) of monomers

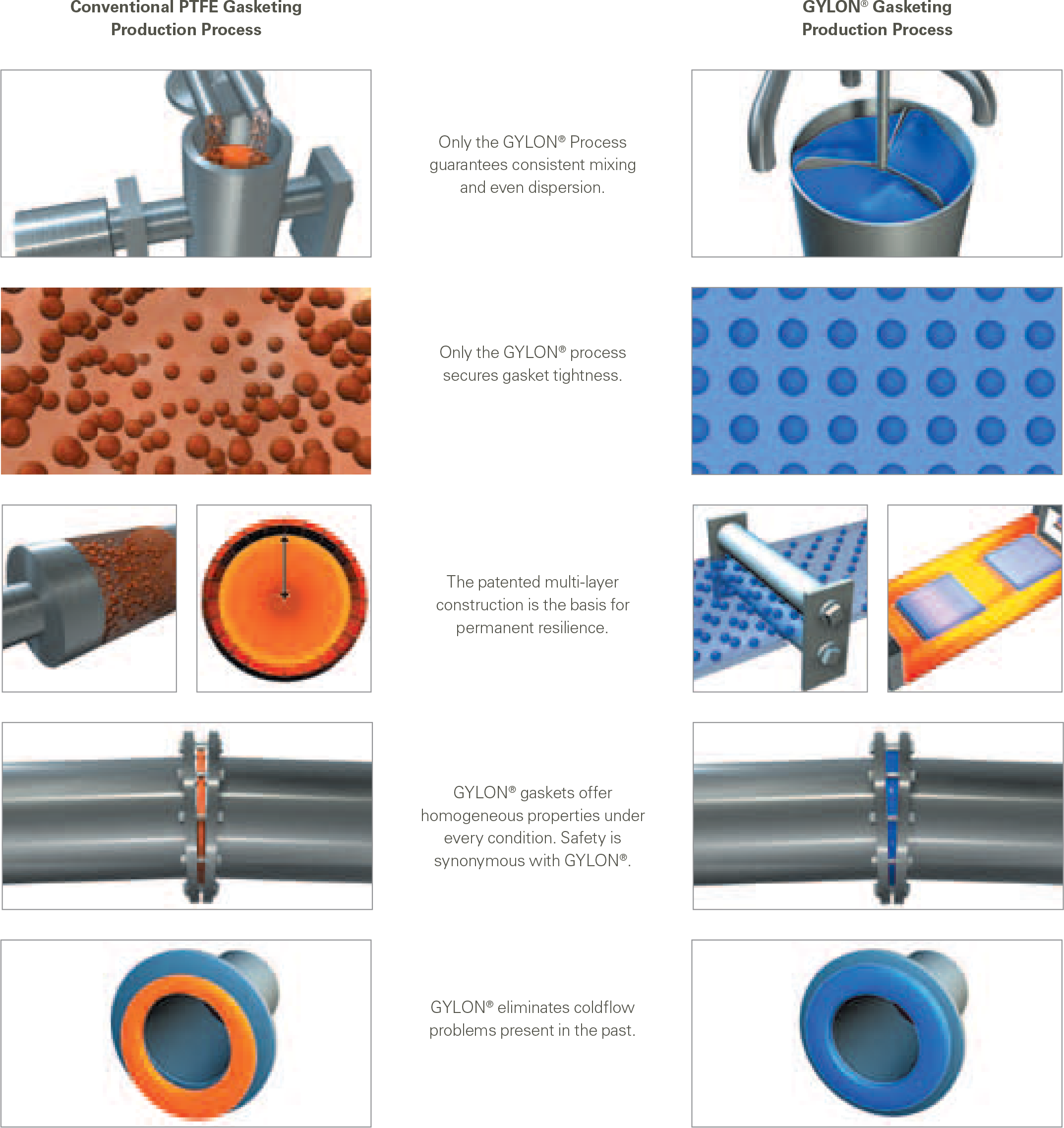

GYLON® – How is it made?

When PTFE* was developed in 1938, the importance of the material to industrial sealing was quickly recognized because of the tremendous chemical resistance characteristics. Skive marks made initial sealing difficult, cold flow caused leakage and premature failure, these problems start to surface.

PTFE was re-engineered to solve these problems and GYLON® is the solution to it.

SPECIFICATIONS

Specifications

- Available in sheet or cut gasket form

- Color: Off-white

- PTFE with barium sulfate

- Meets ABS and FDA specifications

- Min. Temperature: -450°F / -268°C

- Max. Temperature: 500°F / 260°C

- Max. Pressure: 1200 PSI / 83 bar

- Maximum PxT 1/16: 350,000 °F x PSIG / 12,000 bar x °C

- Maximum PxT 1/8: 250,000 °F x PSIG / 8,600 bar x °C

Applications

- Strong caustics

- Moderate acids

- Chlorine

- Gases

- Monomers

- Steam

- Hydrocarbons

- Cryogenics and aluminum fluoride

For oxygen service, specify “Style 3503 for oxygen service.”

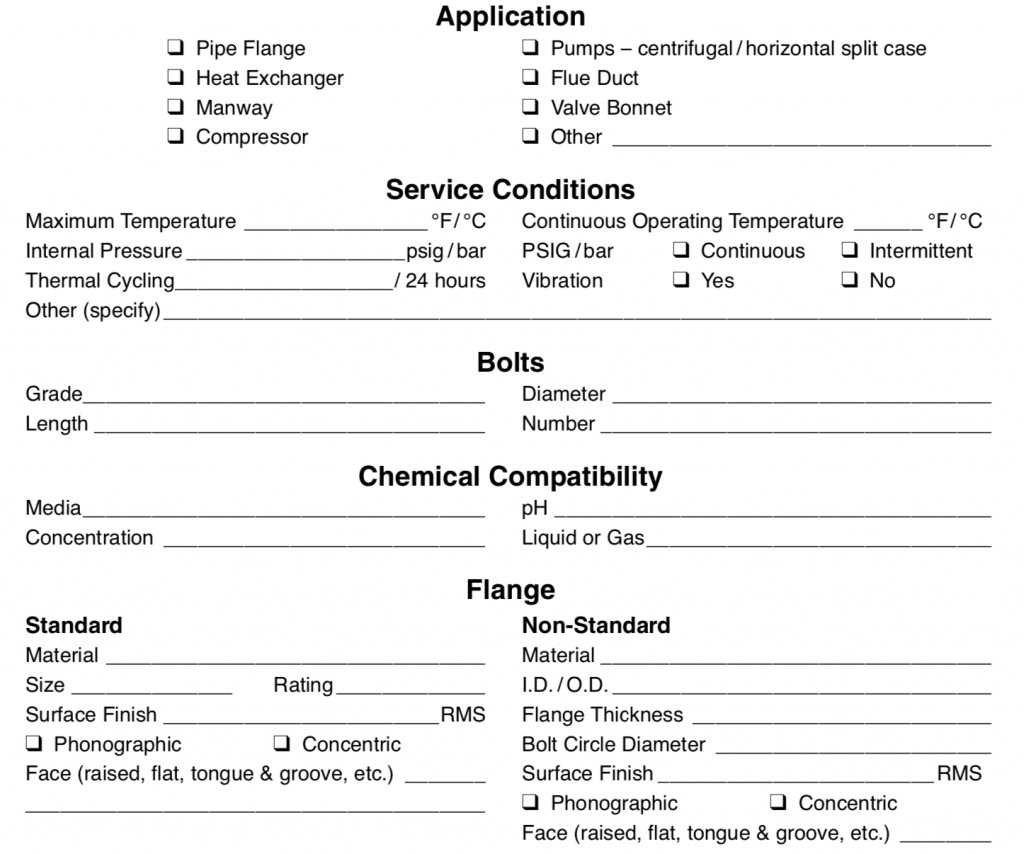

QUESTIONS to ask YOURSELF

- Is my chemical aggressive?

- Is my Gasket wearing out faster than I expect?

- Do I want to have a longer change out period for my Gasket?

Prepare the information below and take to us to make a change!

GASKET CALCULATOR 6.0

Try our Gasket Calculator to find out more about your Gasket!

Gasket-Calculator-6.0_2.xlsx (584 downloads)